Modern PRTD Temperature Sensors and High-Resolution Delta-Sigma ADCs Enable Wide Range High-Accuracy Temperature Measurements

Introduction

This article explains how to achieve high-performance precision, wide-range temperature measurement for platinum resistance temperature detectors (PRTDs), using a data-acquisition system (DAS) comprised of a delta-sigma analog-to-digital converter (ADC) and a modern processor. This DAS offers high performance, yet is cost effective. The development DAS presented here resolves design and mathematical challenges quickly and achieves precision temperature measurement in the PRTD's maximum range (-200°C to +850°C). Platinum resistance temperature detectors, or PRTDs, are absolute temperature-sensing devices that can assure repeatable measurements over temperature ranges of -200°C to +850°C. Platinum, moreover, is very stable and not affected by corrosion or oxidation. PRTDs thus provide optimal performance for precision industrial and medical applications that require precise temperature measurements.1 PRTDs are nearly linear devices. Depending on the temperature range and other criteria, you can make a linear approximation by calculating the PRTD resistance change over a temperature range of -20°C to +100°C.1 For a wider temperature range (-200°C to +850°C) and for higher accuracy, however, the temperature-measurement PRTD standard (EN 60751:2008) defines the behavior of platinum resistance versus temperature by a nonlinear mathematical model called the Callendar-Van Dusen equation. Years ago, implementation of such algorithms could present both technical and cost constraints in DAS design. Today's modern processors like the MAXQ2000 and affordable PCs can resolve these challenges quickly and cost effectively, while providing the user with a friendly graphical display. The Callendar-Van Dusen equation can be used in such a modern DAS to reduce errors to negligible levels for the wide -200°C to +850°C dynamic range. Accuracy will be ±0.3°C or better can be achieved.

详情介绍

Introduction

This article explains how to achieve high-performance precision, wide-range temperature measurement for platinum resistance temperature detectors (PRTDs), using a data-acquisition system (DAS) comprised of a delta-sigma analog-to-digital converter (ADC) and a modern processor. This DAS offers high performance, yet is cost effective. The development DAS presented here resolves design and mathematical challenges quickly and achieves precision temperature measurement in the PRTD's maximum range (-200°C to +850°C). Platinum resistance temperature detectors, or PRTDs, are absolute temperature-sensing devices that can assure repeatable measurements over temperature ranges of -200°C to +850°C. Platinum, moreover, is very stable and not affected by corrosion or oxidation. PRTDs thus provide optimal performance for precision industrial and medical applications that require precise temperature measurements.1 PRTDs are nearly linear devices. Depending on the temperature range and other criteria, you can make a linear approximation by calculating the PRTD resistance change over a temperature range of -20°C to +100°C.1 For a wider temperature range (-200°C to +850°C) and for higher accuracy, however, the temperature-measurement PRTD standard (EN 60751:2008) defines the behavior of platinum resistance versus temperature by a nonlinear mathematical model called the Callendar-Van Dusen equation. Years ago, implementation of such algorithms could present both technical and cost constraints in DAS design. Today's modern processors like the MAXQ2000 and affordable PCs can resolve these challenges quickly and cost effectively, while providing the user with a friendly graphical display. The Callendar-Van Dusen equation can be used in such a modern DAS to reduce errors to negligible levels for the wide -200°C to +850°C dynamic range. Accuracy will be ±0.3°C or better can be achieved.

Designing an Example DAS

The DAS discussed in this article provides a high-resolution, low-noise measurement in the PRTD linear temperature range from -20°C to +100°C. Its accuracy is ±0.15% without implementation of the Callendar-Van Dusen equation. By using a PRTD1000 (PTS1206-1000Ω), a very common platinum RTD that is both size and cost effective, then temperature resolution better than ±0.05°C is achievable within the given range.1 This simple DAS uses a MAX11200 24-bit delta-sigma ADC for data conversion and a low-power, cost-efficient MAXQ2000 processor2 for data acquisition. The DAS implements the linearization algorithm in a PC. Any other capable processor, controller, or DSP could also be used. PRTD devices like the PTS1206-1000Ω are an attractive choice for temperature ranges from -55°C to +155°C because they are available in standard surface-mount device (SMD) sizes, which are very similar to surface-mount resistor packages and priced in the low single-dollar range. For temperature ranges between -50°C and +500°C, thin-film PRTDs represent a cost-effective practical choice.3 Thin-film PRTDs consist of thin-film platinum deposited on a ceramic substrate with a glass-coated platinum element. Resistance and temperature deviation can be controlled to within ±0.06% and ±0.15°C, a tolerance that corresponds to Class A per EN 60751. For high-temperature measurements in liquid or corrosive environments, thin-film PRTDs are often placed inside a protective probe. Figure 1 is a simplified schematic showing the precision DAS developed for this article. It uses the evaluation (EV) kit for the MAX11200 ADC. The MAX11200's GPIO1 pin is set as an output to control the relay calibration switch, which selects either the fixed RCAL resistor or the PRTD. This versatility improves the system precision, reduces the required calculations to those for the initial values of RA and RT, and provides excellent system diagnostics at the same time.

Figure 1. Block diagram of the DAS used for measurements in this article. The DAS includes a provision for system calibration/diagnostics and the MAXQ2000 processor for ADC initialization and data collection with subsequent computer-generated linearization. The DAS dynamically selects either the PRTD measurement or calibration measurement and transmits data though a USB port to the PC. Equation 1 is used to calculate R(t) from the ADC's output code:

|

(Eq. 1) |

Where AADC is the ADC's output code and FS is the ADC's full-scale code (i.e., 223 - 1 for the MAX11200 in a single-ended configuration). According to EN 60751, the PRTD range -200°C to +850°C is divided in two nonlinear temperature zones with different mathematical models. For temperatures between 0°C and +850°C, the linearization equation requires two coefficients based on the following formula:

| R(t) = R(0) × (1 + A × t + B × t2) | (Eq. 2) |

For temperatures from -200°C to 0°C:

| R(t) = R(0)[1 + A × t + B × t2 + (t - 100)C × t3] | (Eq. 3) |

Where R(t) is the PRTD resistance at t°C; R(0) is the PRTD resistance at 0°C; and t is the PRTD temperature in °C. Using Equations 2 and 3, then A, B, and C are calibration coefficients derived from measurements by RTD manufacturers, as specified by IEC 60751: A = 3.9083 × 10-3°C-1

B = -5.775 × 10-7°C-2

C = -4.183 × 10-12°C-4 Note that Equation 2 for temperatures between 0°C to +850°C is a quadratic and, therefore, allows a direct mathematical solution:

| t+800 = [-R(0) × A + ((R(0) × A)2 - 4 × R(0) × B × (R(0) - R(t))1/2]/2 × R(0) × B | (Eq. 4) |

Where R(t) is the PRTD resistance at t°C calculated using Equation 1; R(0) is the PRTD resistance at 0°C; and T is the PRTD temperature in °C. Referring back to Part 1 of this article,1 the first-order linear equation for R(t) shows large nonlinearity errors for temperatures outside the -20°C to +100°C range. Using Equation 2 for R(t) reduces the error to negligible levels.

Figure 2. Data show that nonlinearity errors increase for temperatures outside -20°C to +100°C (purple curve). The errors decrease to negligible levels, except at very low temperatures (blue curve). Table 1 shows that calculations based on Equation 4 provide measurement errors below 0.25°C which, in turn, match the nominal PRTD resistance tables for EN 60751 in the -100°C to +850°C range.

| Table 1. Detailed Temperature Calculations and Absolute Errors | |||||

| Nominal Temperature (°C) | Calibration Coefficients Specified by IEC 60751 | Nominal PRTD Resistance by EN 60751 (Ω) | Calculated Temperature Using Eq 2 (°C) | Absolute Errors (°C) | |

|---|---|---|---|---|---|

| A | B | ||||

| -200.0 | 3.91E-03 | -5.78E-07 | 185.2 | -202.425 | -2.42 |

| -100.0 | 3.91E-03 | -5.78E-07 | 602.56 | -100.208 | -0.21 |

| -70.0 | 3.91E-03 | -5.78E-07 | 723.35 | -70.060 | -0.06 |

| -20.0 | 3.91E-03 | -5.78E-07 | 921.6 | -20.001 | 0.00 |

| 0.0 | 3.91E-03 | -5.78E-07 | 1000 | 0.000 | 0.00 |

| -20.0 | 3.91E-03 | -5.78E-07 | 921.6 | -20.001 | 0.00 |

| 100.0 | 3.91E-03 | -5.78E-07 | 1385.06 | 100.001 | 0.00 |

| 250.0 | 3.91E-03 | -5.78E-07 | 1940.98 | 250.000 | 0.00 |

| 350.0 | 3.91E-03 | -5.78E-07 | 2297.16 | 350.000 | 0.00 |

| 600.0 | 3.91E-03 | -5.78E-07 | 3137.08 | 600.000 | 0.00 |

| 850 | 3.91E-03 | -5.78E-07 | 3904.81 | 850 | 0 |

Temperature measurements with errors below 0.25°C across the -100°C to +850°C range are more than sufficient for most industrial and medical applications. The precision provided by this development DAS is better than the Class A measurement precision prescribed by EN 60751. The ability to arrive at a direct solution (Equation 4) makes this DAS even more attractive because it substantially reduces calculation effort and complexity. Finally, some last thoughts on Equation 3. While allowing a precision solution for temperatures between -200°C to -100°C, Equation 3 is actually a fourth-order polynomial equation that can be resolved only using computer math tools. Those tools will find the best-fit polynomial approximation expressions for the inverse transfer function or use successive approximation methods.

Processing the Data

The firmware on the MAXQ2000-RAX microcontroller manages the following major functions, which are charted in Figure 3:

- Initializes the MAX11200 ADC

- Collects and processes the ADC's output data

- Maintains the USB interface with the PC

During initialization, the MAX11200 ADC goes through the self-calibration process, sets the optimal sampling rate (10sps or 15sps), and enables the input signal buffers. Selection of the sampling rate is very important for temperature measurement in industrial and medical applications. This DAS allows reasonably fast data acquisition with excellent (100dB or better) power line 50Hz/60Hz rejection. The recommended external clock for 60Hz line-frequency rejection is 2.4576MHz, which is effective for data rates of 1, 2.5, 5, 10, and 15sps. For 50Hz line-frequency rejection, the recommended external clock is 2.048MHz, which is effective for data rates of 0.83, 2.08, 4.17, 8.33, and 12.5sps. Use of input signal buffers increases the input impedance to the high-megaohms range. This improves measurement precision because it practically eliminates the shunting effect of the input dynamic current. The firmware also uses the MAX3420E USB interface and, thus, does not require driver software on the PC side. Once the DAS is connected to a PC through USB, the MAX3420E USB module is initialized and the ADC temperature conversion is ready to be transmitted. The software implements algorithms based on Equations 2 and 4. Raw measurement data is processed inside the PC. The processing sequence is also shown in Figure 2. Visuals of the results are shown in Figure 4.

Figure 3. Chart outlines the top-level actions of the DAS firmware and software.

Figure 4. DAS software collects the data generated by the evaluation (EV) kit for the MAX11200 ADC. The PC processes this data using Equation 4 and supplies temperature output in °C or °F. Complementary scope outputs conveniently provide PRTD voltage and code that is useful for system analyses and further engineering development.

Verification of Results

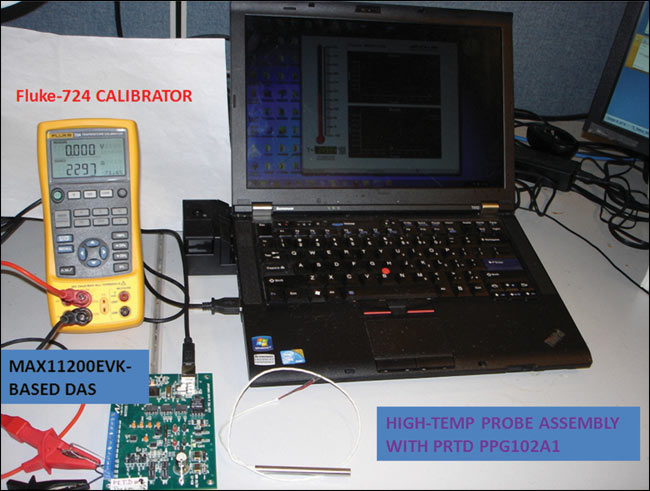

To verify the accuracy of the DAS, we use the Fluke®-724 calibrator. Used as a temperature simulator, the calibrator provides precision equivalent resistance that corresponds to the output of the PRTD-1000O over the -200°C to +600°C range. The DAS dynamically selects either the PRTD measurement or calibration measurement (1.0kΩ, 0.1% resistor) and transmits data though a USB port to the PC. The setup is shown in Figure 5. Table 2 shows that the DAS achieves better than ±0.3°C precision over the -100°C to +600°C temperature range. This performance is overall much better than Class A for EN 60751.

Figure 5. The development system for the DAS. This system features a certified precision calibrator, Fluke-724, used as a temperature simulator to replace a high-temperature PRTD probe.

| Table 2. Temperature Measurement from the DAS Development System | |||

| Temperature by Calibrator Fluke-724 (°C) | Temperature Measured by DAS (Fig. 4) (°C) | Absolute Error (°C) | PRTD Class by IEC 60751 |

|---|---|---|---|

| -200.0 | -202.48 | -2.48 | N/A |

| -100.0 | -100.26 | -0.26 | A |

| -70.0 | -70.11 | -0.11 | A |

| -20.0 | -20.05 | -0.05 | A |

| 0.0 | 0.06 | 0.06 | A |

| 20.0 | 19.94 | -0.06 | A |

| 100.0 | 99.95 | -0.05 | A |

| 250.0 | 249.93 | -0.07 | A |

| 350.0 | 349.90 | -0.10 | A |

| 600.0 | 599.89 | -0.11 | A |

Conclusion

In recent years, PRTDs became desirable devices for a variety of precision temperature-sensing applications where absolute accuracy and repeatability are critical over temperature ranges of -200°C to +850°C. Those applications require a low-noise ADC if the ADC and PRTD are to be connected directly. Together, the PRTD and ADC provide a temperature-measurement system that is ideal for portable sensing applications. This combination offers high performance, yet is cost effective. To accurately measure temperatures in the maximum PRTD range (-200°C to +850°C), nonlinear mathematical algorithms called the Callendar-Van Dusen equations (EN 60751:2008) must be implemented. But just a few years ago implementing those algorithms presented both technical and cost constrains in DAS system design. Today's modern processors like the MAXQ2000 in conjunction with an affordable PC can resolve these challenges quickly and cost effectively.

References

- 应用笔记 4875, "高精度温度测量带动铂电阻温度检测器(PRTD)和Σ-Δ ADC应用"

- PTS Series - Pt-Sensors from Vishay Beyschlag, www.vishay.com/docs/28762/28762.pdf.

- For the thin-film platinum RTD, PPG102A1, used in the example DAS, go to www.ussensor.com/pdfs/prod_rtds_thin_film.pdf.